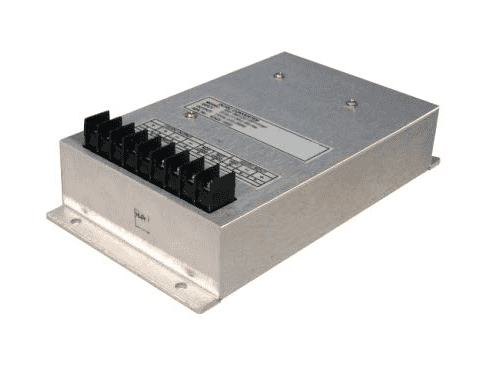

Description

RWY252H

DC/DC Converter Dual Output 200W – Rail Applications

This fully encapsulated, dual output, railway quality DC/DC converter uses a field‐proven high-efficiency power conversion topology to generate 250W output power. The unit has two fully independent, regulated isolated output stages, V1 providing up to 140W and V2 up to 110W. The design is based on the field‐proven RWY 150 and RWY 100 series topology, which has a track record in numerous applications. It is entirely potted with a thermally conductive MIL‐grade silicon rubber compound to ensure immunity to shock, vibration and humidity. The unit is conduction-cooled via a base plate to a heat‐sinking surface. Low component count, large design headroom, and the use of components with established reliability result in a high MTBF. It meets the requirements of EN50155 for Electronic equipment used on rolling stock. The unit is also suitable for transportation, mining, military, marine and other harsh environments.

Features

- Dual output 250 watts

- Designed to rail standards EN50155 & EN50121

- Fully potted with thermally conductive MIL-Spec silicon rubber compound.

- Rugged design for on-board train applications

- Wide input voltage range

- Convection / Conduction cooled: No fans

- Fully isolated input-output 3000VDC

- Overvoltage protection

- Overload and short circuit protection

- MTBF > 160,000hrs

- Specials input/output combinations on request.

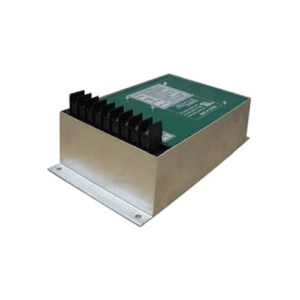

Rugged Mechanical Designs

Helios power supplies are ruggedly constructed and can be customized for specific mechanical requirements. Standard mechanical packages and ruggedization options include:

- Chassis and wall-mountable units invented conduction/convection or fan-cooled enclosures

- DIN-rail and open-frame format available for many designs

- Plug-in (Eurocard) format for modular power systems in 19 inch or 23-inch racks

- Conformal coating and ruggedizing are standard

- Full encapsulation (potting) in a thermally conductive MIL-grade silicon rubber compound with UL94V-0 flammability rating for immunity to high levels of shock and vibration, humidity, moisture, dust, salt, oil, insects and other contaminants

- Enclosure in rugged, IP66- or IP67-rated waterproof, dustproof and explosion-proof die-cast aluminium packages. These enclosures also protect internal electronic boards from condensation and the ingress of oil, salt, sand, insects and other environmental contaminants

- Custom connections

- Portable DC Power Supplies